At the time of writing this post, it is the year of 2013. And although dustless sandblasting equipment has been available for many years now, it seems to be all the rave these days. Over the past few months, I have received an enormous amount of emails from people asking about it. Before I ramble on too much, let me first explain what these units are and how they work.

What is Dustless Sandblasting?

The name “dustless sandblasting” could be used to describe a few equipment types used to control dust such as my plans that show how to make a dust free on-site unit, or the other wet sandblasting unit listed here. But in the industry, dustless sandblasting is commonly referred to the unit that uses compressed air to propel a water and abrasive mixture. The other types don’t use all three of these components.

The name “dustless sandblasting” could be used to describe a few equipment types used to control dust such as my plans that show how to make a dust free on-site unit, or the other wet sandblasting unit listed here. But in the industry, dustless sandblasting is commonly referred to the unit that uses compressed air to propel a water and abrasive mixture. The other types don’t use all three of these components.

It works in a similar manner as the dry pressure pot sandblasting equipment, except it is designed differently to prevent the water from clogging up the abrasive flow.

How it is Designed?

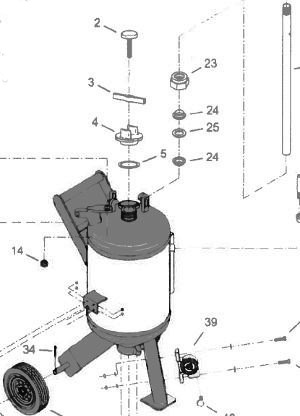

Eventually, I plan on experimenting and making my own by using “some” of the basic steps I wrote in this ebook here. After viewing videos of the dustless sandblasters operating, examining part diagrams, and discussing it with Don P. (an email subscriber) who knows someone that has one, we figured out that it is designed and works in the following notes:

- Overall it is like a pressure pot with a sealed container that holds the water mixed in with the abrasive (often glass beads).

- The intake and exit ports are positioned on the exact opposite sides in comparison to the dry abrasive blasters. First, the compressed air goes in from the bottom and then the mixture of abrasive, air, and water flows out of the top. This flow path prevents the abrasive from clogging.

- It is designed with an upside down cone shaped valve located at the bottom which releases the air up into a metal tube. There is a small gap inbetween the tube and the cone which allows a small amount of water/ abrasive slurry to seep into the air flow and then is carried out the exit port into the nozzle.

- The abrasive to air ratio coming out of the nozzle is adjusted by distancing the space between the cone and metal tube. The metal tube is adjusted at the top with the use of a lever.

Other Facts

- Costs: One of the reason’s that people have been emailing me about these units is because my site mostly deals with providing plans on making your own equipment and these dustless sandblasters can cost a lot of money. Even the small hobby sized units can cost $8,000!

- Uses on Metal: One of the problems with any wet sandblasting unit is that the water can create rust. Typically, a rust inhibitor solution is mixed in with the water to prevent rust from forming. I researched these and the brand I have seen used is called HoldTight 102. Feel free to search for that. I’ve found it online before.

Sounds interesting- the dustless type. I have a large portable unit, 400 cfm .when dust is a problem I use water as the abrasive exits the nozzle then I have rust.would like to know more about the dustless system.

Thanks Randall, I like your idea a lot. One thing you can do for rust is use a rust inhibitor.

I would really like to know what compressor I need to connect the small etching nozzles etc. Can you get fittings that convert to the small size.

Hi Geoff, are you referring to dustless sandblasters or regular ones? Either way, you could fabricate something to use a smaller nozzle.

I believe your diagram shows the fill cap is where the pickup tube should be.

Hello Randall,

I would really appreciate your help. My name is Brendan Walsh and I want to start a MobileSand Blasting Company. The type of work I want to do varies. For example:

I want to do some steel cleaning as I live near the sea where there are fishing boats both wooden and steel. I would also being blasting sandstone and limestone.

One comp[any in England (with agents in Ireland) offer a Blasting pot which will work both wet and dry blasting. They can also supply the ability to run two hoses.

I also want to be able to do a variety of jobs such as inside house work on walls and paint stripping on doors for which they supply units that can be put on my back and is dustless.

They offer a variety of grits and that can be used for different situations including the removal of graffiti.

The pressure they mention is from 40 psi to 100psi. I would need a mobile compression unit , Ingersoll Rand type but I do not know what I should be looking for in a comptressor of this type.

I want to be able to work a spray paint unit also from the compressor and have air fllowing to the helmet unit.

I did Sandblasting many years ago with silica sand and now this is no longer legal here in Ireland.

I know I may be asking a lot but I would be very grateful if you could advise me as to the best way to start this business. Have I chosen the best equipment?

Thanks Randall

If I am asking too much I understand if it takes too much time. The economic situation here in Ireland is very bad and this could be my way out of a financial mess. I will be making out a business plan which will help me apply for grant aid when I get the prices of all of the equipment as well as the prices of the variety of grit I will need.

i need info

Dear sir

I live in Iran.please help me that I have a small dustless blast for my job.

I need drawing dustless blast 60 liters.

Lead me please.

Thanks

Hello, i want the drawings for a dustless blaster, can you please tell me what i need to do?

Thank you

Iam building a dustless blaster and need info on the adjustable media tube.There was mention of a cone and a adjustable pipe height with a lever.The mmlj blaster has this style andi am wondering do you know what it looks like and how it works this is the only missing piece of the puzzle so far

@bowl, I believe it uses an o-ring at the top.

I am interested in dustless blasting system and wonder what the down sides are. It seems to me that the media used to blast and the paint you are blasting needs to go somewhere. Who can tell me where is goes?

Thank you so much for your input

Need plans for dustless blaster thank your

@Gary, most people lay down tarps to collect the abrasive and either reuse it or trash it.

Need plans for a dustless blaster. Wanting to start a mobile blasting business. Thank you

Great work Eric, can we please have the plans or the link to download it, thanks…

Need plans for a dustless blaster. Wanting to start a mobile blasting business also. Thank you.

buenos días, quería saber si tendrías los planos disponibles, soy de argentina y por restricciones de impotacion es imposible en mi caso adquirir equipos similares.- muchas gracias

Hi, Eric

I would like to know the dustless blasting pot, I am quite interested in dustless sandblasting pot, due to my work has too many dust produced when use dry sand blasting pot.

But I don’t know how to download and pay for our design. Could you tell me please ?

would like plans for dustlesblassting how do i get theme thanks

Youz guys are over thinking the wet sand blasting methods

A simple water hose and a win blast nozzle will do the job.

Water induction nozzle

Or a wet ring will do the same thing /clemco-02701-wetblast-attachment

@ Larry, I agree that the attachment is a better way to go. They could be easily made also and a lot lower of a cost. It kinda makes me wonder what the big benefit is of these slurry blasters if the attachments do the same thing. The only thing I can think of it the slurry blasters might reduce the dust slightly better.